Contact us

BIHUADE is a Leading 3.7V Rechargeable LiPo Batteries Manufacturer, Over 30 Years of Rechargeable LiPo Batteries Expert, Competitive Price with High Quality, Flexible Dimensions High Energy Density, Accept small sample order & custom dimensions, Leading Designer and Manufacturer from China in Lithium-Ion Polymer Battery Cell & Packs, with OEM & ODM Great Services.

Leave your requirement in the below footer box, we will reply within 12 hours.

We have thousands of models with LiPo batteries in stock, we can not put every model on our website and inventory changed every day, pls contact us before your consideration, we can offer you the recommendation.

Material Safety Data Sheet

For BIHUADE BATTERY CO., LTD.

Lithium Ion Polymer Battery

Model/type reference………………..: LP452050

Trademark…………………………….: N/A

Nominal Voltage………………………: 3.7V

Typical Capacity………………………: 400mAh, 1.48Wh

Weight………………………………….: 8.0g

L: 50.0mm

Shape and Physical Dimension

(mm)…………………………………….: W: 20.0mm

T: 4.5mm

Version number………………………..: V1.0

Preparation Date………………………: May, 12, 2017~May 22, 2017

Revision date…………………………..: May 22, 2017

_____________________________________________________________________________

IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND OF THE COMPANY/UNDERTAKING

Recommended use of the chemical and restrictions on use

Recommended Use: Used in portable electronic equipments;

Uses advised against:

a)Do not dismantle, open or shred secondary cells or batteries.

b)Do not expose cells or batteries to heat or fire. Avoid storage in direct sunlight.

c)Do not short-circuit a cell or a battery. Do not store cells or batteries haphazardly in a box or drawer where they may short-circuit each other or be shore-circuited by other metal objects.

d)Do not remove a cell or battery from its original packaging until required for use.

e)Do not subject cells or batteries to mechanical shock.

f)In the event of a cdll leaking, do not allow the liquid to come in contact with the skin or eyes. If contact has been made, wash the affected area with copious amounts of water and seek medical advice.

g)Do not use any charge other than that specifically provided for use with the equipment.

h)Observe the plus(+) and minus(-)marks on the cell, battery and equipment and ensure correct use.

i)Do not use any cell or battery which is not designed for use with equipment.

j)Do not mix cells of different manufacture, capacity, size or type within a device.

k)Battery usage by children should be supervised.

I)Seek medical advice immediately if a cell or a battery has been swallowed.

m)Always purchase the battery recommend by the device manufacturer for the equipment.

n)Keep cells and batteries clean and dry.

o)Wipe the cell or battery terminals with a clean dry cloth if they become dirty.

p)Secondary cells and batteries need to be charged before use. Always use the correct charger and refer to the manufacturer’s instructions or equipment manual for proper charging instructions.

q)Do not leave a battery on prolonged charge when not in use.

r)After extended periods of storage, it may be necessary to charge the discharge the cells or batteries several times to obtain maximum performance.

s)Retain the original product literature for future reference.

t)Use only the cell or battery in the application for which it was intended.

u)When possible, remove the battery from the equipment when not in use.

v)Dispose of properly.

2. HAZARDS IDENTIFICATION

Classification

No harm at the normal use. If contact the Electrolyte liquid in the Li-ion Battery, reference as follows:

Classification of the substance or mixture

Classification according to GHS

Acute Toxicity, Oral(Hazard category 4)

Acute Toxicity, Dermal(Hazard category 3)

Skin, irritate(Cagegory 1B)<

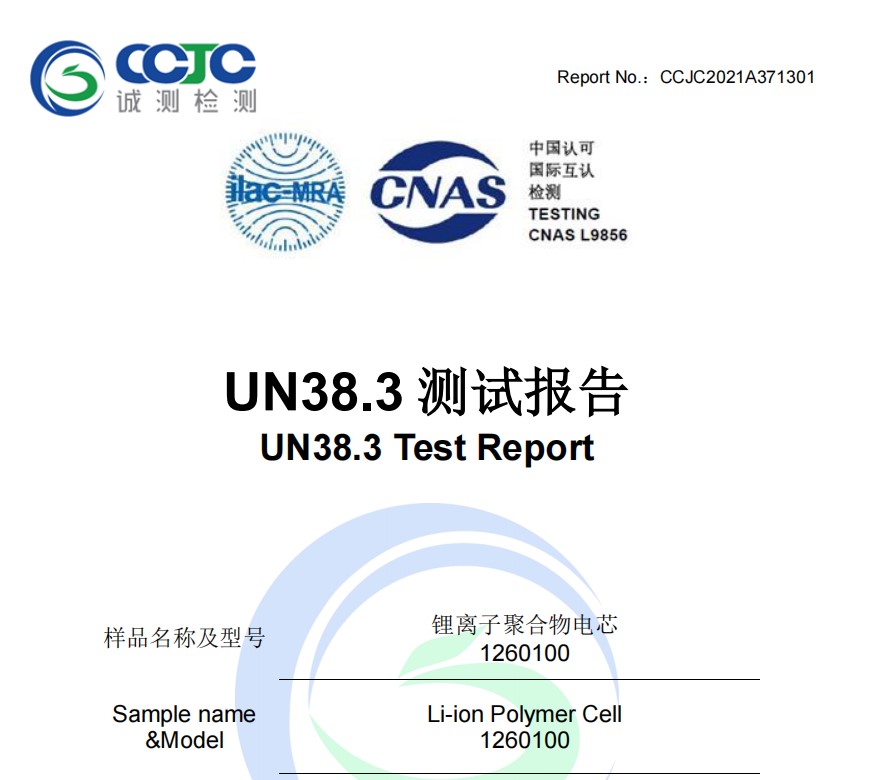

UN38.3 LiPo Batteries

Liter energy battery is a Leading 3.7V Rechargeable LiPo Batteries Manufacturer, Over 30 Years of Rechargeable LiPo Batteries Expert, Competitive Price with High Quality, Flexible Dimensions High Energy Density, Accept small sample orders & custom dimensions, Leading Designer and Manufacturer from China in Lithium-Ion Polymer Battery Cell & Packs, with OEM & ODM Great Services.

Leave your requirement in the below footer box; we will reply within 12 hours.

We have thousands of models with LiPo batteries in stock, we can not put every model on our website and inventory changes every day, pls contact us before your consideration, and we can offer you a recommendation.

UN38.3 LiPo Batteries

What’s LiPo battery UN38.3?

Almost all LiPo batteries need to pass Article 38.3 of the UNITED NATIONS to ensure the safety of LiPo batteries during the transportation of dangerous goods. Manual and Criteria ST/SG/AC. 10/11/Rev.6, 38.3/Amendment 1

Our company Liter energy battery Battery Co. can help customers to apply the UN38.3 test report. Each test takes one month after you get an official UN38.3 test report published by the third-party testing house (BCTC).

LiPo Battery UN38.3 Test Items

UN/DOT 38.2 Transportation Testing for Lithium polymer Batteries 6th edition was issued in 2011. It includes eight sections.

UN38.3.4.1: LiPo Battery Altitude Simulation

Test lithium-ion cells and batteries shall be stored at an 11.6 kPa or less for at least six hours at an ambient temperature of 20±5℃.

Lithium-ion cells and lithium-ion batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or LiPo battery after testing is not less than 90% of its voltage immediately before this procedure. The requirement relating to energy is not applicable to test cells and batteries at fully discharged states.

UN38.3.4.2: LiPo Battery Temperature Test

Test lithium-ion cells and lithium-ion batteries are to be stored for at least six hours at a test temperature equal to -72±5℃, followed by storage for at least six hours at a test temperature similar to -40±2℃. The maximum time interval between test temperature extremes is 30 minutes. This procedure is repeated ten times, after which all test cells and batteries are stored for 24 hours at ambient temperature.

Lithium-ion cells and lithium-ion batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or LiPo battery after testing is not less than 90% of its voltage immediately before this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

UN38.3.4.3: LiPo Battery Oscillation

Test lithium-ion cells and lithium-ion batteries are firmly secured to the platform of the vibration machine without distorting the cells in such a manner as to faithfully transmit the vibration. The vibration shall be a sinusoidal waveform with a logarithmic sweep between seven Hz and 200 Hz and back to seven Hz traversed in fifteen minutes. This cycle shall be repeated twelve times for a total of 3 hours for each of three mutually perpendicular mounting positions of the cell. One of the directions of vibration must be perpendicular to the terminal face.

The logarithmic wavelength sweep shall differ for cells and batteries with a gross mass of not more than 12 kg(cells and small batteries), and for batteries with a total mass of more than 12 kilograms (large lithium-ion batteries).

For lithium-ion cells and small lithium-ion batteries: from 7 Hz, a peak acceleration of 1 gn is maintained until 18 Hz is reached. The amplitude is then maintained at 0.8mm (1.6mm total excursion), and the frequency increases until a peak acceleration of eight gn occurs ( approximately 50Hz). Peak acceleration of eight gn is then maintained until the frequency increases to 200Hz.

Lithium-ion cells and lithium-ion batteries meet this demand if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or LiPo battery after testing is not less than 90% of its voltage immediately before this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

UN38.3.4.4: LiPo Battery Collision

Test lithium-ion cells and batteries shall be secured to the testing machine employing a rigid mount that will support all mounting surfaces of each test LiPo battery. Each lithium-ion cell shall be subjected to a half-sine shock of peak acceleration of one hundred and fifty gn and pulse duration of 6 milliseconds. Alternatively, large cells may be subjected to a half-sine shock of peak acceleration of fifty gn and pulse duration of 11 milliseconds. Each LiPo battery shall be subjected to a half-sine shock of peak acceleration depending on the mass of the LiPo battery. The pulse duration shall be six milliseconds for small lithium-ion batteries and 11 milliseconds for large lithium-ion batteries. The formulas below are provided to calculate the appropriate minimum peak accelerations.

Cells and batteries meet this requirement if there is no mass loss, no leakage, no venting, no disassembly, no rupture, and no fire and if the open circuit voltage of each test cell or LiPo battery after testing is not less than 90% of its voltage immediately before this procedure. The requirement relating to voltage is not applicable to test cells and batteries at fully discharged states.

UN38.3.4.5: LiPo Battery External Short-Circuit

The lithium-ion cell or LiPo battery to be tested shall be temperature stabilized so that its external case temperature reaches 57±4℃. Then the cell or LiPo battery shall be subjected to a short circuit condition with a total external resistance of fewer than 0.1 ohms at 57±4℃. This short circuit condition is continued for at least one hour after the cell or LiPo battery external case temperature has returned to 57±4℃.

Cells and batteries meet this requirement if their external temperature does not exceed 170℃ and there is no disassembly, no rupture, and no fire during the test and within six hours after the test.

UN38.3.4.6: LiPo Battery Impression

Test Procedure- Crush (applicable to prismatic, punch, coin/button cells and cylindrical cells not more than 18mm in diameter). A cell or component cell is to be crushed between two flat surfaces. The crushing is gradual, with a speed of approximately 1.5cm/s at the first point of contact. The crushing is to be continued until the beginning of the three options below is reached. (a) the applied force reaches 13 kN±0.78 kN;

A prismatic or punch cell shall be crushed by applying force to the widest side. A button/coin cell shall be destroyed by using power on its flat surfaces. For cylindrical cells, the crushing force shall be applied perpendicular to the longitudinal axis. Each test cell or component cell is to be subjected to one curse only. The test sample shall be observed for a further six h. The test shall be conducted using test cells or component cells that have not previously been subjected to other tests.

lithium cells and component cells meet this requirement if their external temperature does not exceed 170℃ and there is no disassembly, no rupture, and no fire during the test and within six hours after the test.

UN38.3.4.7: LiPo Battery Overcharge

The charge current shall be twice the manufacturer’s recommended maximum continuous charge current. Tests are to be conducted at ambient temperature. The duration of the test shall be 24 hours. The minimum voltage of the test shall be as follows: When the manufacturer’s recommended charge voltage is not more than 18v, the minimum voltage of the test shall be the lesser of two times the maximum charge voltage go the LiPo battery or 22v.

There is no disassembly and no fire during the test and within seven days after the test.

UN38.3.4.8: LiPo Battery Forced discharge

Each lithium-ion cell shall be forced discharge at ambient temperature by connecting it in series with a 12v D.C. power supply at an initial current equal to the maximum discharge current specified by the manufacturer. The specified discharge current is to be obtained by connecting a resistive load of the appropriate size and rating in series with the test cell. Each cell shall be forced discharged for a time interval (in hours) equal to its related capacity divided by the initial test current) in ampere).

There is no disassembly and no fire during the test and within seven days after the test.

Certificated UN38.3 LiPo Batteries

Lithium-ion Batteries and lithium-polymer Batteries are getting more popular in modern consumer electronics, Liter energy battery manufacturers offer both lithium-ion batteries and lithium-polymer batteries.

3.7V Reliable Leading Rechargeable Lithium Polymer Batteries Manufacturer, 30 Years Rechargeable Battery Expert, Competitive Price with High Quality, Flexible Dimensions High Energy Density, Accept small sample order & custom dimensions, Accept OEM & ODM orders.

LiPo Batteries also named Liter energy batteryy battery, Li-polymer battery, Lithium polymer battery, Liter energy battery battery, We sell all kinds of rechargeable lipo batteries, such as Cylindrical Lithium polymer batteries, Round Lithium polymer batteries, Special Lithium polymer batteries, Ultra-thin Lithium polymer batteries, RC Lithium polymer battery, 3.7V Lithium polymer, Flat Lithium polymer batteries, Standard LiPo Batteries, Micro Lithium polymer batteries, rechargeable Lithium polymer batteries, etc.

Lithium-ion batteries also named Li-ion Battery, Liter energy battery Manufacturer Supply kinds of Rechargeable lithium-ion batteries, such as Lithium-Ion Battery LP18650(diameter 18mm, length 65mm), Lithium-Ion Battery LP26650(diameter 26mm, length 65mm), Lithium-Ion Battery LP21700(diameter 21mm, length 70mm), Micro Lithium-Ion Batteries (diameter 4mm, length 4mm).

We design and manufacture custom Lithium Polymer Batteries’ packs to customers’ specifications. If you need a specific Lithium Polymer Batteries pack, we can advise the best possible solution, Customized Your Lithium Polymer Batteries in Any Size, Capacity, and Shape, Meet Your Different Needs by Assembling the Lithium Polymer Battery in Series and Parallel.

355990 2400mAh Standard LiPo Battery with connector JST PHR-2 A

Model 355990 2400mAh Standard LiPo Battery with connector JST PHR-2 AType3.7V Standard LiPo Battery...

555870 2900mAh Standard LiPo Battery with connector FPCB

Model 555870 2900mAh Standard LiPo Battery with connector FPCBType3.7V Standard LiPo BatteryCapacit...

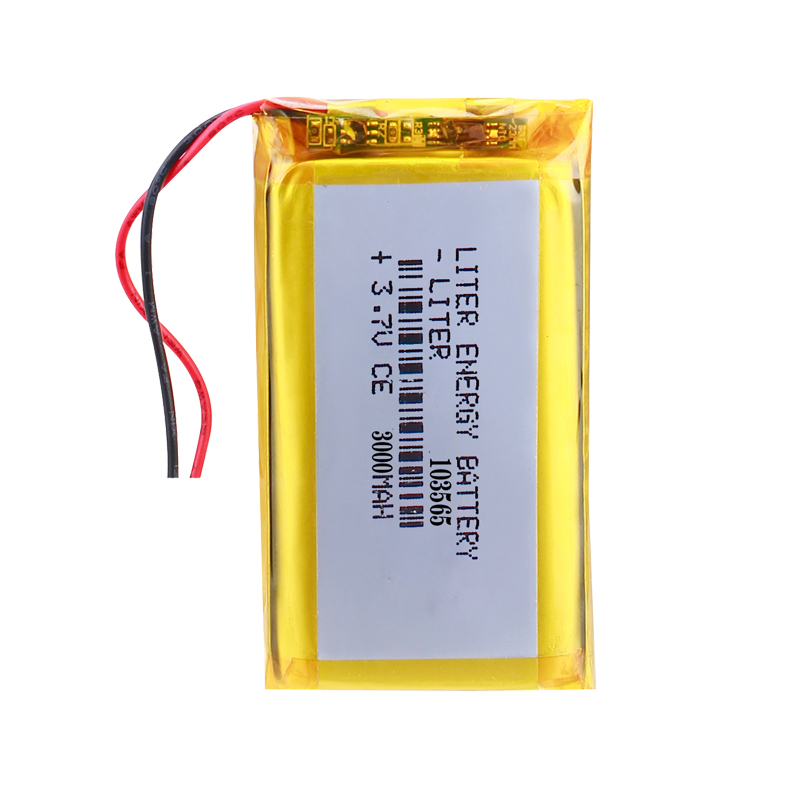

3.7V 103565 3000mAh Standard LiPo Battery with connector two pairs wires two connectors

Model3.7V 103565 3000mAh Standard LiPo Battery with connector two pairs wires two connectorsType3....

271244 90mAh 3.7V Rechargeable LiPo Battery Batteries

271244 90mAh 3.7V Rechargeable LiPo Battery BatteriesBattery Type 271244 90mAh 3.7V Rechargeable ...

321522 70mAh 3.7V Rechargeable LiPo Battery Batteries

321522 70mAh 3.7V Rechargeable LiPo Battery BatteriesBattery Type 321522 70mAh 3.7V Rechargeable ...

301025 55mAh 3.7V Rechargeable LiPo Battery Batteries

Model 301025 55mAh 3.7V Rechargeable LiPo Battery BatteriesType3.7V LiPo batteryCapacity55mAh LiPo ...

350840 95mAh 3.7V Rechargeable LiPo Battery Batteries with connector JST ACHR-03V-S B

Model 350840 95mAh 3.7V Rechargeable LiPo Battery Batteries with connector JST ACHR-03V-S BType3.7V...

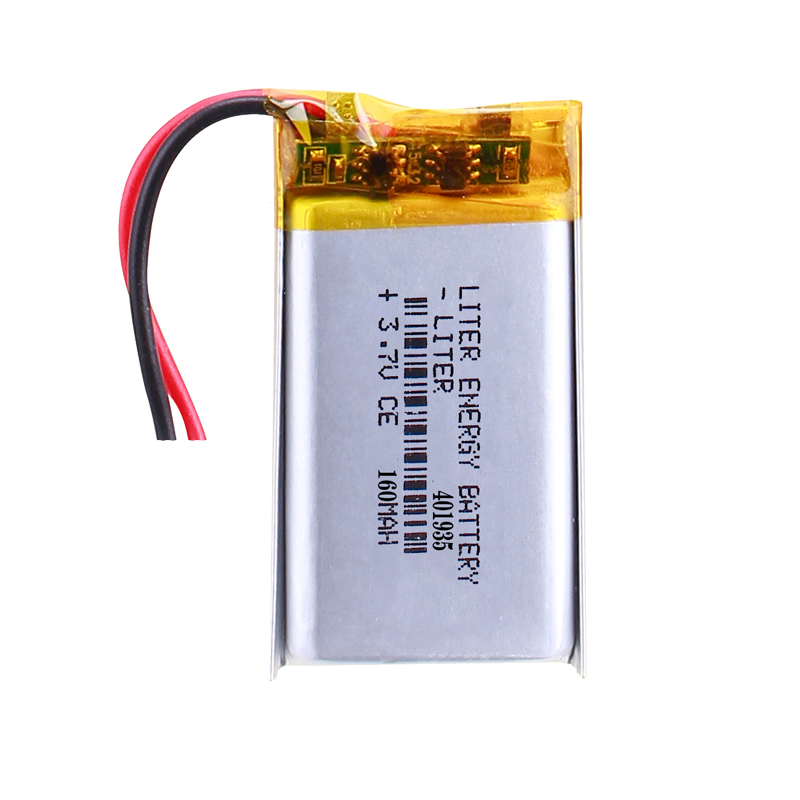

401935 1.5A 160mAh 3.7V Rechargeable LiPo Battery Batteries

Model 4019035 1.5A 160mAh 3.7V Rechargeable LiPo Battery BatteriesType3.7V LiPo Battery Batteries...