Contact us

BIHUADE is a Leading 3.7V Rechargeable LiPo Batteries Manufacturer, Over 30 Years of Rechargeable LiPo Batteries Expert, Competitive Price with High Quality, Flexible Dimensions High Energy Density, Accept small sample order & custom dimensions, Leading Designer and Manufacturer from China in Lithium-Ion Polymer Battery Cell & Packs, with OEM & ODM Great Services.

Leave your requirement in the below footer box, we will reply within 12 hours.

We have thousands of models with LiPo batteries in stock, we can not put every model on our website and inventory changed every day, pls contact us before your consideration, we can offer you the recommendation.

Material Safety Data Sheet

For BIHUADE BATTERY CO., LTD.

Lithium Ion Polymer Battery

Model/type reference………………..: LP452050

Trademark…………………………….: N/A

Nominal Voltage………………………: 3.7V

Typical Capacity………………………: 400mAh, 1.48Wh

Weight………………………………….: 8.0g

L: 50.0mm

Shape and Physical Dimension

(mm)…………………………………….: W: 20.0mm

T: 4.5mm

Version number………………………..: V1.0

Preparation Date………………………: May, 12, 2017~May 22, 2017

Revision date…………………………..: May 22, 2017

_____________________________________________________________________________

IDENTIFICATION OF THE SUBSTANCE/PREPARATION AND OF THE COMPANY/UNDERTAKING

Recommended use of the chemical and restrictions on use

Recommended Use: Used in portable electronic equipments;

Uses advised against:

a)Do not dismantle, open or shred secondary cells or batteries.

b)Do not expose cells or batteries to heat or fire. Avoid storage in direct sunlight.

c)Do not short-circuit a cell or a battery. Do not store cells or batteries haphazardly in a box or drawer where they may short-circuit each other or be shore-circuited by other metal objects.

d)Do not remove a cell or battery from its original packaging until required for use.

e)Do not subject cells or batteries to mechanical shock.

f)In the event of a cdll leaking, do not allow the liquid to come in contact with the skin or eyes. If contact has been made, wash the affected area with copious amounts of water and seek medical advice.

g)Do not use any charge other than that specifically provided for use with the equipment.

h)Observe the plus(+) and minus(-)marks on the cell, battery and equipment and ensure correct use.

i)Do not use any cell or battery which is not designed for use with equipment.

j)Do not mix cells of different manufacture, capacity, size or type within a device.

k)Battery usage by children should be supervised.

I)Seek medical advice immediately if a cell or a battery has been swallowed.

m)Always purchase the battery recommend by the device manufacturer for the equipment.

n)Keep cells and batteries clean and dry.

o)Wipe the cell or battery terminals with a clean dry cloth if they become dirty.

p)Secondary cells and batteries need to be charged before use. Always use the correct charger and refer to the manufacturer’s instructions or equipment manual for proper charging instructions.

q)Do not leave a battery on prolonged charge when not in use.

r)After extended periods of storage, it may be necessary to charge the discharge the cells or batteries several times to obtain maximum performance.

s)Retain the original product literature for future reference.

t)Use only the cell or battery in the application for which it was intended.

u)When possible, remove the battery from the equipment when not in use.

v)Dispose of properly.

2. HAZARDS IDENTIFICATION

Classification

No harm at the normal use. If contact the Electrolyte liquid in the Li-ion Battery, reference as follows:

Classification of the substance or mixture

Classification according to GHS

Acute Toxicity, Oral(Hazard category 4)

Acute Toxicity, Dermal(Hazard category 3)

Skin, irritate(Cagegory 1B)<

UL2054 Certification of LiPo Batteries – Liter energy battery Battery Co.,Ltd

UL2054 Certification Scope

1.1 UL2054 certification requirements cover portable primary (non-rechargeable) and secondary (rechargeable) lipo batteries for use as a power supply in goods. These lipo batteries consist of either a single electrochemical cell or two or more lipo cells connected in parallels or series, or both, that convert chemical energy into electrical energy by chemical reaction.

1.2 UL2054 certification requirements intend to reduce the risk of explosion or fire when lipo batteries are working in a device. The proper use of these lipo batteries in a particular application is dependent on their use in a complete product that complies with the requirements applicable to such a product.

1.3 UL2054 certification requirements are intended to cover lipo batteries for general use. They do not include the combination of the lipo battery and the host product, which are covered by specifications in the host product standard.

1.4 UL2054 certification requirements are also intended to reduce the risk of injury to persons due to fire or explosion when lipo batteries are removed from a product to be transported, stocked, or discarded.

1.5 UL2054 certification requirements do not cover the toxicity risk that results from the ingestion of a lipo battery or its contents, nor the risk of injury to somebody that occurs if a lipo battery is open to provide access to its contents.

The General of UL2054 Certification

2.1.1 Instead of the UL2054 certification requirements outlined in table 6.1, lipo cells constructed of lithium metal, lithium alloy, or lithium-ion that are used in batteries shall meet the conditions in the standard for lipo batteries UL 1642.

2.2 Units of measurement

2.3 Terminology

2.4 Components

2.4.1 Except as indicated in 2.4.2, a component of a product covered by this standard shall comply with UL2054 certification requirements for the element. See appendix for a list of rules covering parts used in the products covered by this UL2054 standard.

2.4.2 A component is not required to comply with a specific requirement that: Involves a feature or characteristic not needed for the application of the element in the product covered by UL2054 standard or is superseded by a condition in UL2054 standard.

2.4.3 A component shall be used following its rating established for the intended conditions of use.

2.4.4 Specific parts are incomplete in construction features or restricted in performance capabilities. The components are intended for use only under limited conditions, such as certain temperatures not exceeding specified limits, and shall be used only under those specific conditions.

Glossary of UL2054 Certification

4.1.1 The casing of a lipo cell or single-cell battery, or the enclosure of a lipo battery pack shall have the strength and rigidity required to resist the possible abuses, that it is exposed to during its intended use, in order to reduce the risk of fire or injury to persons.

4.1.2 The casing of a lipo battery pack shall be rigid enough to prevent flexing. A tool providing the construction advantage of pliers, screwdriver, hacksaw, or similar device, shall be the minimum automated capability required to open the casing.

4.1.3 For lipo battery packs with plastic outer enclosures, the external ring of the battery shall be designed such that it is not capable of being opened using simple tools, such as a screwdriver. The enclosure shall be ultrasonically welded or secured by equivalent means. Adhesives complying with the adhesive requirements of the Standard for Polymeric Materials – Use in Electrical Equipment Evaluations, UL 746C, single-use, or tamper-proof screws are considered equivalent means.

4.1.4 The outer case body of the lipo battery shall be classed as V-1 or less flammable in the minimum part thickness under the Standard for Polymeric Materials — Use in Electrical Equipment Evaluations, UL 746C.

Exception: Materials are not required to be classed as V-1 or less flammable when they comply with the Enclosure Flammability – 20 mm (3/4 inch) Flame test specified in the Standard for Polymeric Materials– Use in Electrical Equipment Evaluations, UL 746C.

4.1.5 Openings in lipo battery pack enclosures shall minimize to prevent damage to lipo cells, connections, and internal circuitry and too short of electrical spacings within the lipo battery pack. Enclosure openings shall not be located over lipo cells that do not comply with the rigid casing requirements of 4.1.2 or overprotective circuitry and connections where damage or shorting from debris entering the enclosure could result in a hazard.

4.2 Electrolyte

4.2.1 A lipo cell shall not contain pressurized vapor or liquid that expels materials forcibly when the lipo battery casing is punctured with a grinding wheel under laboratory conditions at a temperature of 23 ±2°C (73±3.6°F).

4.3 External LiPo Battery Pack Connectors

4.3.1 An external lipo battery pack connector shall be constructed to prevent unpremeditated short-circuiting of its terminals unless the pack meets the limited power supply requirements of the Limited Power Source Test, Section 13. Examples of methods to avoid inadvertent short-circuiting include recessing the terminals, providing circuitry that prevents inadvertent short-circuiting, providing covers over the terminals, use of keyed connectors, and the like.

4.3.2 Insulating material for external battery pack connectors, outside the enclosure, shall have a V-2 minimum flame rating unless the pack meets the limited power source requirements of the Limited Power Source Test, Section 13. External connectors forming part of the fire enclosure shall be V-1 minimum.

4.4 Printed wiring boards

4.4.1 Printed wiring boards positioning lipo battery circuit components shall be rated V-1 minimum

4.5 LiPo systems only

4.5.1 The voltage of each lipo cell or each cellblock consisting of parallel-connected plural cells should not exceed the upper limit of the charging voltage specified by the battery manufacturer.

4.5.2 For the lipo battery consisting of a single cell or a separate cellblock, it should be confirmed that the charging voltage of the cell does not exceed the upper limit of the charging voltage specified by the battery manufacturer.

4.5.3 For the lipo battery consisting of series-connected single cells or series-connected cellblocks, it should be confirmed that the voltages of any one of the individual cells or single cellblocks does not exceed the upper limit of the charging voltage, specified by the cell manufacturer, by monitoring the energy of every single cell or the single cellblocks.

4.5.4 Compliance for 4.5.1 – 4.5.3 can be achieved through analysis of the lipo battery protection circuit or, if unable to determine through analysis, then through monitoring values during the test of Section 13A.

️Performance

Performance of UL2054 Certification

5.1 LiPo batteries are to be tested as described in Sections 9 through 24. Section 12, Forced-Discharge Test, is applicable only to lipo cells intended to be used in multi-cell series applications, such as lipo battery packs. The Battery Enclosure Tests, Sections 18 — 21 (including the 250 N Steady Force, Mold Stress Relief, and Drop Impact Tests) are intended only for batteries that have a plastic outer enclosure.

5.2 With the exclusion of the Projectile Test of Section 22, lipo cells and batteries shall not explode or catch fire as a result of the tests in this standard. For the Shock Test, Section 16, Vibration Test, Section 17, 250 N Steady Force Test, Section 19, Mold Stress Relief Test, Section 20, Drop Impact Test, Section 21, and the Temperature Cycling Test, Section 24 the samples shall also not vent or leak. For these tests, unacceptable leakage is deemed to have occurred when the resulting mass loss exceeds the values shown in Table 5.1, Venting, and Leakage Mass Loss Criteria.

5.3 Deleted August 12, 2008

5.4 Certain end product devices require that the power output of a lipo battery be limited. The Limited Power Source Test described in Section 13 is to be used to determine whether a lipo cell or battery is suitable in such applications where fire hazards may otherwise exist.

Samples of UL2054 Certification

6.1 Unless otherwise indicated, new lipo cells or batteries in the fully charged state are to be used for the tests described in Sections 9 – 24. The test schedule and the number of samples to be used in each analysis are shown in Tables 6.1 and 6.2, for cell testing and battery pack testing, respectively.

6.2 When a lipo battery pack is tested in accordance with Table 6.2, the lipo cells comprising that battery pack shall also be tested in accordance with Table 6.1 if they have not already been.

6.3 All lipo batteries shall be wholly charged in accordance with the battery manufacturer’s specifications prior to testing except for the samples to be subjected to the Abnormal Charging and Abusive Overcharge Tests, which shall be discharged to the manufacturer specified endpoint voltage using the manufacturer specified current prior to testing.

Important Test Considerations of UL2054 Certification

7.1 As some lipo batteries explode in the tests described in Sections 9 — 24, it is crucial that personnel be protected from the flying fragments, explosive force, sudden release of heat, chemical bums, and noise results from such explosions. The test field is to be well ventilated to protect the organization from possible harmful fumes or gases.

7.2 The temperatures on the surface of the lipo battery casings shall be monitored during the tests described in Sections 9, 10, 11, 14, and 15. All personnel involved in the testing of batteries are to be instructed never to approach a lipo battery until the surface temperature returns to ambient temperature.

7.3 The tests described in Section 22, Projectile Test, shall be conducted in a separate room or room equipped with an adequate safety barrier separating the test area from the observer.

Temperature Measurements of UL2054 Certification

8.1 Temperatures are to be contained by thermocouples consisting of wires not larger than 24 AWG (0.21 mm2) and not smaller than 30 AWG (0.05 mm2) and a potentiometer-type instrument.

8.2 The temperature measurements on the lipo batteries are to be made with the measuring junction of the thermocouple held tightly against the outer casing of the battery.

Electrical Tests of UL2054 Certification

Short-Circuit Test

9.1 Lipo cells shall comply with 9.1 — 9.6.

(Underwriter Laboratories Inc. approved battery cell used in the EUT according to UL1642)

9.2 Each fully charged test lipo cell, in turn, is to be short-circuited by connecting the positive and negative terminals of the battery with a circuit load having a resistance load of 80 ± 20 mohm. The temperature of the lipo battery case is to be recorded during the test. The lipo battery is to discharge until a fire or explosion is obtained, or until it has reached an unloaded state of fewer than 0.2 volts and the case temperature has returned to ±10°C (±18°F) of ambient temperature.

9.3 Tests are to be transferred at 20 ± 5°C (68 ± 9°F), and at 55 ± 2°C (131 ± 4°F). The lipo cells are to reach equilibrium at 20 ± 5°C (68 ± 9°F) or 55 ± 2°C (131 ± 4°F) as applicable, before the terminals are connected.

9.4 A lipo cell is to be tested individually unless the battery manufacturer indicates that it is intended for use in series or parallel. For series or parallel use, additional tests on five sets of lipo batteries are to be conducted using the maximum number of lipo cells to be covered for each configuration as specified by the battery manufacturer.

9.5 A lipo cell is to be tested without the assistance of protective devices unless such protective mechanisms are integral to the lipo cell construction. When a protective device actuates during the test, the test shall be repeated with the lipo cell connected to the maximum load that does not cause the protective equipment to open.

9.6 The lipo batteries shall not explode or catch fire. The temperature of the exterior cell or battery casing shall not exceed 150°C (302°F) for lithium chemistries.

9.7 LiPo battery packs shall comply with 9.8 —9.12.

Exception: LiPo battery packs consisting of a single cell, in which the cell has already been subjected to the tests in 9.1 – 9.6 need not be submitted to the standards in 9.8 – 9.12

9.8 Each fully charged test lipo battery pack, in turn, is to be short-circuited by connecting the positive and negative terminals of the battery with a circuit load having a resistance load of 80 ± 20 m ohm. The temperature of the lipo battery case is to be recorded during the test. The lipo battery is to discharge until a fire or explosion is obtained, or until it is completely released and the cell case temperature has returned to ±10°C (±18°F) of ambient temperature.

9.9 Tests are to be transferred at 20 ± 5°C (68 ± 9°F) and at 55 ± 5°C (131 ± 4°F). The lipo batteries are to reach steadiness at 20 ± 5°C (68 ± 9°F) or 55 ± 5°C (131 ± 4°F), as applicable, before the terminals are joined.

9.10 LPo battery pack constructions are to be subjected to a single fault across any protective device in the load circuit of the battery under test. When protective materials actuate during the trial, the examination shall be repeated with the lithium-ion battery pack connected to the maximum load that does not cause the protective devices to open.

Exception: A positive temperature coefficient device which complies with the tests specified in Standard for Thermistor-Type Devices, UL 1434, the Standard for Automatic Electrical Controls for Household and Similar Use, Part 1: General Requirements, UL 60730-1A, or other protective devices determined to be reliable, may remain in the circuit without being faulted. See Appendix A for additional component standards.

9.11 One of the above five test sample lipo battery packs, tested at 20 ±5°C (68 ±9°F) shall be evaluated with the following additional conditions in place. The terminals are to be subjected to a short circuit condition with a minimum length of 16 AWG (1.3 mm2) bare copper wire. The test is to be conducted on a tissue paper covered softwood surface, and the sample battery pack and exposed leader is to be covered with a single layer of cheesecloth.

9.12 For all samples tested, the lipo batteries shall not explode or catch fire, and the tests shall not result in chemical leaks caused by cracking, rupturing, or bursting of the cell casing. The temperature of the internal cell casings shall not exceed 150°C (302°F) for lithium chemistries. For battery pack samples tested in accordance with 9.11, the cheesecloth and tissue paper shall not catch fire.

Abnormal Charging Test of UL2054 Certification

10.1 Primary lipo batteries (for example, lipo cells, single lipo batteries, or lipo battery packs) shall comply with 10.2 –10.5 (Secondary lipo battery pack).

10.2 LiPo batteries discharged to the battery manufacturer’s estimated capacity are to be used for this test. The lipo batteries are to be tested in an ambient temperature of 20 ± 5°C (68 ± 9°F).

10.3 Each wholly discharged test sample battery is to be subjected to a charging current of three times the current lc, designated by the battery manufacturer, by connecting it in opposition to a dc-power supply. The test time is to be calculated using the formula: in which it is the charging time in an hour. C is the capacity of the lipo cell /lipo battery in ampere-hours, and lc is the maximum charging current, in amperes, particularized by the battery manufacturer. The minimum charging time is to be 7 hours.

Exception: At the battery manufacturer’s preference, test currents more significant than the specified three times rated Ic can be applied to expedite the test timeframe, with the minimum charging times as seven hours.

10.4 When a protective device that has been examined for the purpose, actuates during the test, the test shall be repeated with the battery supply connected to the maximum load that does not cause the protective device to open. Protective equipment that has not been investigated for the purpose shall be short-circuited.

10.5 The lipo batteries shall not explode or catch fire. For lipo battery pack samples, tests shall not result in chemical leaks caused by cracking, rupturing, or bursting of the series casing.

10.6 Secondary lipo cells shall comply with 10.7 – 10.9 (Underwriter Laboratories Inc. approved battery cell used in the EUT according to UL1642)

10.7 The lipo cells are to be tested in an ambient temperature of 20 ± 5°C (68 ± 9°F). Each lithium-ion battery shall be discharged at a constant current of 0.2 C/1 hours, to a manufacturer specified discharge endpoint voltage.

10.8 The lipo cells are to be charged with a constant maximum specified charger output voltage and a current limit of three times the maximum current Ic, particularized by the battery manufacturer. Charging duration is the time required to reach the manufacturer’s specified end-of-charge condition plus seven further hours.

10.9 A lipo cell is to be tested without the assistance of protective devices unless such protective mechanisms are either integral to the cell constructions or have been investigated for the purpose. A piece of re-settable protective equipment that actuates during the test shall be allowed to reset, and the examination shall be resumed, cycling as often as necessary to complete the test. When a protective device operates during the test (whether re-settable or not), the test is repeated with the same charging time, but with the lipo cell connected to the maximum load that does not cause the protective devices to operate. A piece of protective equipment that is not integral to the cell, and that has not been investigated for the purpose is to be short-circuited.

10.10 Secondary lipo battery packs shall comply with 10.11 — 10.13.

10.11 The lipo batteries are to be tested in an ambient temperature of 20±5°C (68±9°F). A thermocouple is to be attached to the lipo cells of each test sample battery. Each lithium-ion battery shall be discharged at a constant current of 0.2C/1 hour, to a manufacturer specified discharge endpoint voltage.

10.12 Each of the test sample batteries are to be subjected to the following overcharge states, in sequential order. a) The lipo battery is to be initially charged using a constant current charging mode with a current limit of three times the highest current Ic, particularized by the battery manufacturer until the maximum specified charger output voltage is reached. At that point, the lipo battery is to be charged with a constant maximum specified charger output voltage and a current limit of three times the maximum current Ic. Charging duration is the time required to reach the manufacturer’s specified end-of-charge condition plus seven additional hours. The temperature on the lipo cell casing shall be monitored. A re-settable protective device such as a PTC that actuates during the test shall be allowed to reset, and the examination shall be resumed, cycling as often as necessary, but no less than ten times, to complete the test. Automatic reset devices are allowed to cycle during the trial. When an overcurrent protective device operates during the trial, the test is repeated with the same charging time, but with the battery connected to the maximum load that does not cause the protective devices to operate. b) The charge condition in accordance with (a) shall be conducted with each single component fault that is likely to occur in the charging circuit and which would result in overcharging of the battery. Exception No. 1: A protective device determined to be reliable may remain in the loop without being faulted. See 2.4 and Appendix A. Exception No. 2: For batteries without protective devices, the overcharge condition(s) in (b) does not apply.

10.13 The lipo batteries shall not explode or catch fire. For lipo battery pack samples, tests shall not result in chemical leaks caused by cracking, rupturing, or bursting of the internal cell casing.

Abusive Overcharge Test of UL2054

(Underwriter Laboratories Inc. approved lipo battery cell used in the EUT according to UL1642)

11.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

11.2 LiPo batteries are to be subjected to a continuous charging current at ten times the C5 amp rate, using a supply voltage satisfactory to maintain the ten times C5 amp rate throughout the duration of the test. During the trial, the temperature is to be marked on the internal cell casing of each sample. The test is to continue until the lipo cell or battery explodes, vents, or a single operation protective device operates, and the temperature of the internal cell casing reaches steady-state requirements or returns to ambient. If a PTC or other re-settable protection device works during the test, it is to be reset a minimum of 10 times during the trial. An automatic reset device is allowed to cycle during the trial.

11.3 During the tests, lipo batteries supplied with protective devices shall be subjected to a single part fault using any individual fault condition, which is likely to occur in the charging circuit and which would result in overcharging of the lipo battery.

Exception: Protective devices determined to be reliable, may remain in the circuit without being faulted. See Appendix A.

11.4 The samples shall not explode or catch fire.

11.5 At least one of the five lipo batteries shall be subjected to the test outlined in 11.2 and 11.3 with a constant current charge five times the C5 rate (for example: at the C rate) with a supply voltage sufficient to maintain that rate throughout the duration of the test

Forced-Discharge Test of UL2054 Certification

12.1 This test is intended for lipo cells that are to be used in multi-cell applications, such as lipo battery packs. The LiPo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

12.2 For multi-cell series configurations without parallel strings, a wholly discharged cell is to be force-discharged by connecting it in series with fully charged LiPo batteries of the same kind. The quantity of entirely charged cells to be connected in series with the discharged cell is to equal the total number of cells in the pack less one.

12.3 For multi-cell series arrangements with parallel strings, a wholly discharged identical line is to be force-discharged by connecting it in series with entirely charged cells of the same kind. The quantity of wholly charged cells to be connected in series with the discharged parallel string is to equal the total number of cells in the pack less the number of cells in the discharged parallel line.

12.4 Each of the five battery packs shall be prepared as described in 12.2 or 12.3, as applicable.

12.5 Once the completely discharged LiPo cells (or string of cells) are connected in series with the specified number of fully charged cells, and the resultant battery pack is to be short-circuited.

12.6 The positive and negative terminals of the sample are to be connected with copper wire with a resistance load of 80 ± 20 m ohms. The battery is to discharge until a fire or explosion is obtained, or until it has reached a completely discharged state and the cell case temperature has returned to ±10°C (±18°F) of ambient temperature.

12.7 During the tests, LiPo batteries supplied with protective devices shall be subjected to a single component fault using any single fault condition, which is likely to occur in the discharge circuit and which would result in excessive discharge of the battery.

Exception: A positive temperature coefficient device which complies with the applicable tests specified in the Standard for Thermistor-Type Devices, UL 1434 and the Standard for Automatic Electrical Controls for Household and Similar Use, Part 1: General Requirements, UL 60730-1A, or other protective devices determined to be reliable, may remain in the circuit without being faulted. See Appendix A for additional component standards.

12.8 The lipo batteries shall not explode or catch fire.

Limited Power Source Test of UL2054 Certification

13.1 The LiPo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

13.2 A lipo battery intended to be a limited power source shall comply with one of the following:

a) The output is constitutionally limited in compliance with Table 13.1, or b) A linear or nonlinear impedance limits the output in compliance with Table 13.1. If a positive temperature coefficient equipment is used, it shall:

1) Comply with the Standard for Thermistor-Type Devices, UL 1434, or 2) Pass the tests particularized in the Manufacturing Deviation and Drift Section, the Endurance Section, and the Manufacturing Deviation and Drift Section and the Endurance Section in the Annex for Requirements for Controls Using Thermistors of the Standard for Automatic Electrical Controls for Household and Similar Use, Part 1: General Requirements, UL 60730-1; or 3) Meet the requirements in the Standard for Automatic Electrical Controls for Household and Similar Use, Part 1: General Requirements, UL 60730-1 for a device for type 2.AL Action; c) A regulating network or an integrated protection circuit (IC) current limiter, limit the output in compliance with table 13.1, both under normal operating conditions and after any single simulated fault in the regulating network or IC current limiter (open circuit or short circuit); or d) An overcurrent protective device is used, and the output is limited in compliance with Table 13.2.

13.3 Where an overcurrent protective device is used, it shall be a fuse or a non-adjustable, no auto-reset, electromechanical equipment.

13.4 LiPo batteries shall be fully charged when conducting the measurements for Uoc ISC, and S according to Tables 13.1 and 13.2.

13.5 The non-capacitive load referenced in Tables 13.1 and 13.2 shall be adjusted to develop maximum measured values of current (Isc) and power (S) that can be obtained over the time limits noted in Tables 13.1 and 13.2. Simulated faults in a regulating network required according to 13.2 items (c) above are applied under these load conditions.

13.6 LiPo batteries that meet the limited power supply requirements may be marked “Limited Power Source” “LPS” to indicate that they are considered to be a limited power source. LiPo batteries that do not meet these requirements, regardless of terminal design, shall not be marked to indicate that they are a limited power supply and are assigned to applications where a limited power source is not required.

13A LiPo Pack Component Temperature Test

13A.1 A lipo battery pack with enclosure shall be subjected to a regular temperature test under both input (charging) and output (discharging) conditions. As a result of this testing, temperatures on temperature-sensitive components shall not exceed the limits outlined in table 13A.1

13A.2 For the output loading temperature test, a wholly charged lipo battery pack, shall be subjected to a constant resistive loading across the output terminals of the lipo battery pack with the output load current set to just below the operating limit of the discharging protection circuit. Temperatures are monitored until thermal stabilization or until the pack is at its specified endpoint voltage, whichever comes first.

13A.3 The input loading temperature test shall be conducted on a fully discharged battery pack, discharged at a constant current of 0.2C/1 hour to a manufacturer specified discharge endpoint voltage.

13A.4 For the input loading temperature test, a wholly discharged lipo battery shall be subjected to a CCCV charging method with the maximum charging voltage not to exceed the battery manufacturer’s suggested maximum charging voltage limits. During the test, the charging current shall not exceed three times the maximum charge current or the operating limit of the charging protection circuit, whichever is less, during the test. Temperatures are monitored until thermal stabilization or until the pack is at its fully charged state, whichever comes first.

13A.5 Temperatures are considered to be stabilized when three progressive readings are taken at intervals of 10 percent of the previously elapsed duration of the test, but not less than 15 minutes, indicate no further increase.

13A.6 Protective devices within the lipo battery pack shall not operate during the test.

13A.7 Temperatures are monitored on surfaces of parts using thermocouples. Thermocouples are to consist of 30 AWG wires. Larger size wires may be used, but they shall not exceed 24 AWG and shall not be big enough to result in a heat sink condition on the part under test.

13A.8 During the normal temperature test, temperature measurement T shall not exceed (Tmax + Tamb-Tma).

13B Lipo Battery Pack Surface Temperature Test

13B.1 A lipo battery pack with enclosure shall be subjected to a regular temperature test under both input (charging) and output (discharging) conditions.

13B.2 For the output loading temperature test, a fully charged lipo battery pack, shall be subjected to a constant resistive loading across the output terminals of the lithium-ion battery pack with the output load current set to just below the operating limit of the discharging protection circuit. Temperatures are monitored until thermal stabilization or until the pack is at its specified endpoint voltage, whichever comes first.

13B.3 The input loading temperature test shall be conducted on a fully discharged lipo battery pack, discharged at a constant current of 0.2C/1 hour to a battery manufacturer specified discharge endpoint voltage.

13B.4 For the input loading temperature test, a fully discharged lipo battery shall be subjected to a CCCV charging method with the maximum charging voltage not to exceed the battery manufacturer’s recommended maximum charging voltage limits. During the test, the charging current shall not exceed three times the maximum charge current or the operating limit of the charging protection circuit, whichever is less, during the test. Temperatures are monitored until thermal stabilization or until the pack is at its wholly charged state, whichever comes first.

13B.5 Temperatures are considered to be stabilized when three successive readings are taken at intervals of 10 percent of the previously elapsed duration of the test, but not less than 15 minutes, indicate no further increase.

13B.6 Protective devices within the LiPo battery pack shall not operate during the test.

13B.7 Temperatures are monitored on the accessible surfaces of the pack enclosure using thermocouples. Thermocouples are to consist of 30 AWG wires. Larger size wires may be used, but they shall not exceed 24 AWG.

13B.8 During the regular temperature test, temperature measurement T shall not exceed (Tmax + Tamb − Tma)

Mechanical Test of UL2054 Certification Crush Test

The component LiPo cell has approved by Underwriter Laboratories Inc., according to UL1642.

14.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

14.2 A lipo battery is to be crushed between two flat surfaces. The force for the crushing is to be applied by a hydraulic ram or a similar force device. The flat surfaces are to be brought in contact with the cells, and the crushing is to be continued until an applied force of 13 ± 1.0 KN (3000 ± 224 pounds) is reached. Once the highest force has been obtained, it is to be released.

14.3 A cylindrical or prismatic lipo battery is to be crushed with its longitudinal axis parallel to the flat surfaces of the crushing apparatus. A prismatic lithium-ion battery is also to be rotated 90 degrees around its longitudinal axis so that both the wide and narrow sides will be subjected to the crushing force. Each lithium-ion battery is to be subjected to a crushing force in only one direction. Separate samples are to be used for each test.

14.4 A coin or button lipo battery is to be crushed with the flat surface of the battery parallel with the flat surfaces of the crushing apparatus.

14.5 The lipo batteries shall not explode or catch fire.

Impact Test of UL2054 Certification

The component lipo cell has approved by Underwriter Laboratories Inc., according to UL1642.

15.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

15.2 A test sample lipo battery is to be placed on a flat surface. A 15.8 mm (518 inches) diameter bar is to be located across the center of the sample. A 9.1 ±0.46 kg (20 ±1 pound) weight is to be dropped from a height of 610 ±25 mm (24 ±1 inch) onto the sample.

15.3 A barrel-shaped or prismatic battery is to be impacted with its longitudinal axis parallel to the flat surface and perpendicular to the longitudinal axis of a 15.8 mm (5/8 inch) diameter curved surface lying across the center of the test sample. A prismatic battery is also to be rotated 90 degrees around its longitudinal axis so that both the wide and narrow sides will be subjected to the impact. Each sample lipo battery is to be subjected to only a single impact. Separate samples are to be used for each test.

15.4 A coin or button lipo battery is to be impacted with the fiat surface of the test sample parallel to the flat surface and the 15.8 mm (5/8 inch) diameter curved surface lying across its center.

15.5 The samples shall not explode or catch fire.

Shock Test of UL2054 Certification

The component lipo cell has approved by Underwriter Laboratories Inc., according to UL1642.

16.1 The lipo cell is to be secured to the testing machine by means of a rigid mount that supports all mounting surfaces of the cell. Each cell shall be subjected to a total of three shocks of equal greatness. The shocks are to be applied in each of three mutually vertical directions unless it has only two tomahawks of symmetry, in which case only two directions shall be tested. Each shock is to be applied in a direction normal to the face of the cell. For each shock, the lithium-ion cell is to be accelerated in such a manner that during the initial three milliseconds, the minimum average acceleration is 75 g (where g is the local acceleration due to gravity). The peak acceleration shall be between 125 and 175 g. The lithium-ion cells shall be tested at a temperature of 20 ±5°C (68 ±9°F).

16.2 The samples shall not explode or catch fire.

16.3 The sample shall be examined 6 hours after testing and shall not vent or leak as described in 5.2.

Vibration Test of UL2054 certification

The component lipo cell has approved by Underwriter Laboratories Inc., according to UL1642.

17.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

17.2 A lipo battery is to be constrained to simple harmonic motion with an amplitude of 0.8 mm (0.03 inch) [1.6 mm (0.06 inch) total maximum excursion].

17.3 The recurrence is to be varied at the rate of 1 hertz per minute between 10 and 55 hertz and return in not less than 90 nor more than 100 minutes. The lipo battery is to be tested in three mutually perpendicular directions. For a lipo battery that has only two axes of symmetry, the lipo battery is to be tested perpendicular to each axis.

17.4 The samples shall not explode or catch fire.

17.5 The sample shall be examined 6 hours after testing and shall not vent or leak as described in 5.2.

️LiPo Battery Enclosure Test

Vibration Test of UL2054 Certification

18.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

18.2 lipo batteries with outer plastic enclosures shall be subordinated to the tests described in Sections 19, 20, and 21. Lithium-ion batteries with outer enclosures made from materials other than plastic shall be subjected to the tests specified in Sections 19 and 21

250 N Steady Force Test of UL2054 Certification

19.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F).

19.2 External enclosures of the lipo battery pack are to be controlled to a steady force of 250 ±10 N (56 ±2 pounds-force) for a period of 5 seconds, applied in turn to the top, bottom and sides of the lithium-ion battery pack enclosure by means of a suitable test tool providing contact over a circular plane surface 30 mm (1.2 inches) in diameter.

19.3 The lipo batteries shall not explode or catch fire. The outer battery enclosure shall not crack to the extent that the lipo cells or any protective devices are exposed. Openings in the enclosure created as a result of the application of the 250 N steady force shall meet the standards of 4.1.5

19.4 The lipo batteries shall be examined 6 hours after testing and shall not vent or leak as described in 5.2.

Mold Stress Relief Test of UL2054

20.1 Each of the three lipo batteries is to be placed in a full-draft circulating-air oven maintained at a uniform temperature of 70°C (1 58°F). The samples are to remain in the oven for 7 hours.

Exception: If the maximum temperature, T, recorded on the battery pack thermoplastic enclosure parts, obtained during the normal temperature test of Section 13A exceeds 60°C (140°F), then the oven temperature is to be maintained at a temperature equal to T + 10°C (50°F).

20.2 Deleted effective November 11, 2011

20.2.1 To prevent hazards from overheating energized cells, samples shall either be fully discharged prior to conditioning or provided with ”dummy” cells, which are representative of the actual cells

20.3 After careful removal from the oven and after returning to room temperature following the conditioning described in 20.3, the samples shall show no evidence of mechanical damage that would result in damage to cells or protective circuitry. In addition, The battery enclosures shall not crack, warp, or melt to the extent that the cells or any protective devices are exposed. Openings in the enclosure created as a result of the conditioning shall meet the criteria of 4.1.5

Drop Impact Test of UL2054 Certification

21.1 The lipo batteries are to be tested in an ambient temperature of 20 ±5°C (68 ±9°F)

Exception: Lipo battery packs operating plastic enclosures that are intended for use in 0°C (32°F) temperatures shall be conditioned for 3 hours at 0°C (or temperature specified if lower than 0°C) prior to conducting the drop test, which shall be transferred shortly after removing the samples from the cold conditioning.

21.2 Each of three samples is to be dropped from a height of 1 m (3.28 ft), so it strikes a concrete surface in the position that is most likely to produce the adverse results in 21.3. Each sample is to be dropped three times.

21.3 The samples shall not explode or catch fire.

21.4 The sample shall be examined 6 hours after testing and shall not vent or leak as described in 5.2, and the integrity of the protective devices shall be maintained.

21.5 The outer battery enclosure shall not decipher to the extent that cells or any protective devices are exposed. Openings in the enclosure created as a result of the drop impact(s) shall meet the criteria of 4.1.5

Fire Exposure Tests of UL2054

Projectile Test

The component lipo cell has approved by Underwriter Laboratories Inc., according to UL1642.

22.1 When constrained to the test described in 22.2 — 22.5, no part of an exploding lipo cell or lipo battery shall create a hole in the wire screen cage or penetrate the wire screen cage such that some or all of the cell or battery protrudes through the screen cage.

22.2 Each test sample cell or battery is to be placed on a screen that covers a 102 mm (4 inches) diameter hole in the center of a platform table. The screen is to be constructed of a steel wire mesh having 20 openings per inch (25.4 mm) and a wire diameter of 0.43 mm (0.017 inches.

22.3 The screen is to be mounted 38 mm (1-1/2 inch) above a burner. The fuel and airflow rates are to be set to provide a bright blue flame that causes the supporting screen to glow a bright red.

22.4 An eight-sided covered wire cage, 610 mm (2 feet) across, and 305 mm (1 foot) high, made from metal screening, is to be placed over the test sample. See Figure 22.1. The metal screening is to be constructed from 0.25 mm (0.010 inches) diameter aluminum wire with 16— 18 wires per inch (25.4 mm> in each direction.

22.5 The sample is to be heated and shall remain on the screen until it explodes, or the cell or battery has ignited and burned out. It is not required to secure the sample in place unless it is at risk of falling off the screen before the test is completed. When required, the sample shall be secured to the screen with a single wire tied around the sample.

Precautions for safe handling

Handle in accordance with good industrial hygiene and safety practice. Avoid contact with skin, eyes, and clothing. Wear personal protective equipment.

Wash thoroughly after handling. Use this material with adequate ventilation.

The product is not explosive.

️Environmental Tests of UL2054

Heating Test

The component lipo cell has approved by Underwriter Laboratories Inc., according to UL1642.

23.1 The lipo battery shall not explode or catch fire when subjected to the test described in 23.2 — 23.4.

23.2 A lipo battery is to be heated in gravity convection or circulating air oven with an initial temperature of 20 ±5°C (68 ±9° F).

23.3 The temperature of the oven is to be raised at a rate of 5 ±2°C (9 ±3.6° F) per minute to a temperature of 130 ±2°C (266 ±3.6°F) and remain at that temperature for 10 minutes.

23.4 The lipo batteries shall return to room temperature (20 ±5°C) and then be examined.

Temperature Cycling Test

The component cell has approved by Underwriter Laboratories Inc., according to UL1642.

24.1 The lipo batteries are to be placed in a test chamber and subjected to the following cycles: a) Raising the chamber-temperature to 70±3°C (158±5°F) within 30 minutes and maintaining this temperature for 4 hours. b) Reducing the chamber temperature to 20±3°C (68±5°F) within 30 minutes and maintaining this temperature for 2 hours. c) Reducing the chamber temperature to minus 40±3°C (minus 40±5°F) within 30 minutes and maintaining this temperature for 4 hours. d) Raising the chamber temperature to 20±3°C (68±5°F) within 30 minutes. e) Repeating the sequence for a further nine cycles. f) After the 10th cycle, storing the batteries for a minimum of 24 hours at 20±5°C (68±9°F) prior to examination.

24.2 The samples shall not explode or catch fire. In addition, the samples shall not vent or leak, as described in 5.2.

2️5 MARKING

25.1 A lipo battery shall be legibly and enduringly marked with:

a) The battery manufacturer’s name, trade name, or trademark or other characteristic markings by which the company responsible for the product may be identified;

b) A characteristic (catalog or model) number or the equivalent;

c) The electrical rating in Vdc and Ah. (Secondary lithium-ion batteries may be marked in Wh rather than Ah);

d) The date or another dating period of manufacture not exceeding any three consecutive months.

Exception No. 1: The battery manufacturer’s identification may be in a visible code if the product is identified by the brand or trademark owned by a private labeler.

Exception No. 2: The date of production may be abbreviated, or maybe in a nationally accepted conventional code or in a code declared by the battery manufacturer, provided that the code:

a) It does not repeat in less than ten years.

b) It does not require reference to the production records of the battery manufacturer to determine when the product was produced.

25.2 When a battery manufacturer produces the lipo battery at more than one factory, each lithium-ion battery shall have a distinctive marking to identify it as the product of an appropriate factory.

25.3 A lipo battery or the smallest unit package or directions provided with each battery shall include the following announcements or equivalent:

a) An attention word, such as – Caution, Warning, or Danger.

b) A brief description of possible hazards associated with the mishandling of the lithium-ion battery, such as burn hazard, fire hazard, an explosion hazard.

c) A list of actions to take to avoid possible hazards, such as do not crush, disassemble, dispose of in fire, or similar actions, and for primary lithium-ion batteries, do not charge.

d) Education regarding replacement lithium-ion batteries if the batteries are replaceable by the user.

25.3.1 A lipo battery pack shall be marked with the following or equivalent:

CAUTION: Risk of Fire and Burns. Do Not Open, Crush, Heat Above (battery manufacturer’s specified maximum temperature), or Incinerate. Follow Manufacturer’s Instructions ‖ This wording or equivalent shall also be included in the instructions packaged with the lithium-ion battery pack.

Exception No. 1: A lipo battery pack not provided with an enclosure need not be marked but shall include the above wording or equivalent in the instructions supplied with the pack.

Exception No. 2: If space does not permit marking on the battery, the marking may be on the smallest unit package.

25.4 The battery manufacturer’s specified charging preparations shall be included for secondary lipo batteries. Primary batteries shall consist of instructions indicating that the batteries shall not be charged.

25.5 A lipo cell or battery that is less than 32 mm (1.25 inches) in diameter by 3.8 mm (0.15 inches) thick shall include the following marking or equivalent on the smallest unit package or instructions provided with each lipo cell or battery: “Caution — Never put lithium-ion batteries in mouth. If swallowed, contact your physician or local poison control center.”

25.6 lipo batteries, which meet the requirements of the Limited Power Source Test, Paragraph 13.4, may include the marking ” Limited Power Source‖ or ―LPS.”

UL2054 & UL1642 Certificated LiPo Batteries

Lithium-ion Batteries and lithium-polymer Batteries are getting more popular in modern consumer electronics, Liter energy battery manufacturers offer both lithium-ion batteries and lithium-polymer batteries.

3.7V Reliable Leading Rechargeable Lithium Polymer Batteries Manufacturer, 30 Years Rechargeable Battery Expert, Competitive Price with High Quality, Flexible Dimensions High Energy Density, Accept small sample order & custom dimensions, Accept OEM & ODM orders.

LiPo Batteries also named Liter energy batteryy battery, Li-polymer battery, Lithium polymer battery, Liter energy battery battery, We sell all kinds of rechargeable lipo batteries, such as Cylindrical Lithium polymer batteries, Round Lithium polymer batteries, Special Lithium polymer batteries, Ultra-thin Lithium polymer batteries, RC Lithium polymer battery, 3.7V Lithium polymer, Flat Lithium polymer batteries, Standard LiPo Batteries, Micro Lithium polymer batteries, rechargeable Lithium polymer batteries, etc.

Lithium-ion batteries also named Li-ion Battery, Liter energy battery Manufacturer Supply kinds of Rechargeable lithium-ion batteries, such as Lithium-Ion Battery LP18650(diameter 18mm, length 65mm), Lithium-Ion Battery LP26650(diameter 26mm, length 65mm), Lithium-Ion Battery LP21700(diameter 21mm, length 70mm), Micro Lithium-Ion Batteries (diameter 4mm, length 4mm).

We design and manufacture custom Lithium Polymer Batteries’ packs to customers’ specifications. If you need a specific Lithium Polymer Batteries pack, we can advise the best possible solution, Customized Your Lithium Polymer Batteries in Any Size, Capacity, and Shape, Meet Your Different Needs by Assembling the Lithium Polymer Battery in Series and Parallel.

355990 2400mAh Standard LiPo Battery with connector JST PHR-2 A

Model 355990 2400mAh Standard LiPo Battery with connector JST PHR-2 AType3.7V Standard LiPo Battery...

555870 2900mAh Standard LiPo Battery with connector FPCB

Model 555870 2900mAh Standard LiPo Battery with connector FPCBType3.7V Standard LiPo BatteryCapacit...

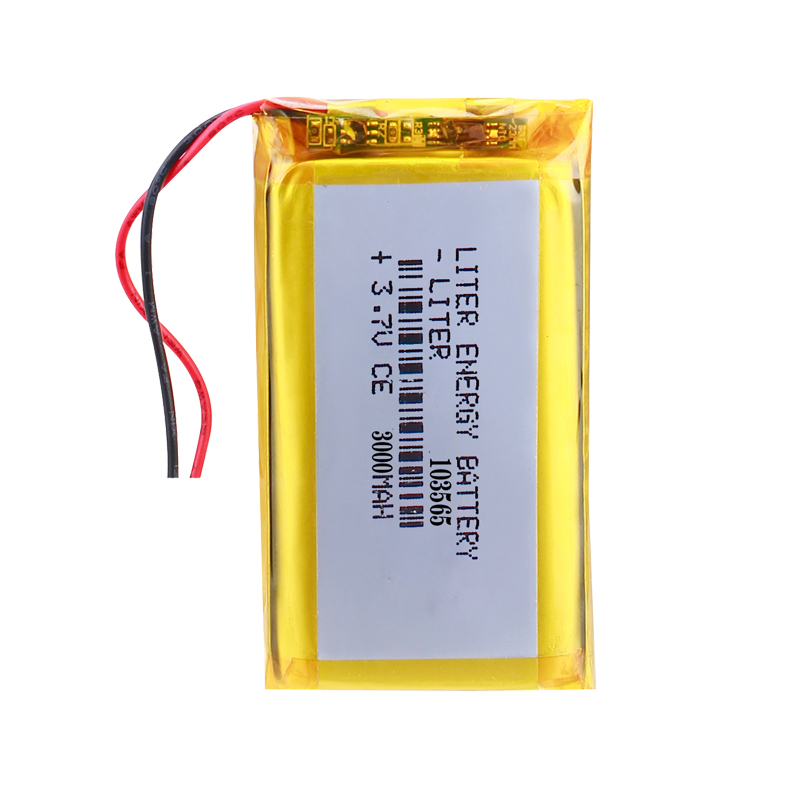

3.7V 103565 3000mAh Standard LiPo Battery with connector two pairs wires two connectors

Model3.7V 103565 3000mAh Standard LiPo Battery with connector two pairs wires two connectorsType3....

271244 90mAh 3.7V Rechargeable LiPo Battery Batteries

271244 90mAh 3.7V Rechargeable LiPo Battery BatteriesBattery Type 271244 90mAh 3.7V Rechargeable ...

321522 70mAh 3.7V Rechargeable LiPo Battery Batteries

321522 70mAh 3.7V Rechargeable LiPo Battery BatteriesBattery Type 321522 70mAh 3.7V Rechargeable ...

301025 55mAh 3.7V Rechargeable LiPo Battery Batteries

Model 301025 55mAh 3.7V Rechargeable LiPo Battery BatteriesType3.7V LiPo batteryCapacity55mAh LiPo ...

350840 95mAh 3.7V Rechargeable LiPo Battery Batteries with connector JST ACHR-03V-S B

Model 350840 95mAh 3.7V Rechargeable LiPo Battery Batteries with connector JST ACHR-03V-S BType3.7V...

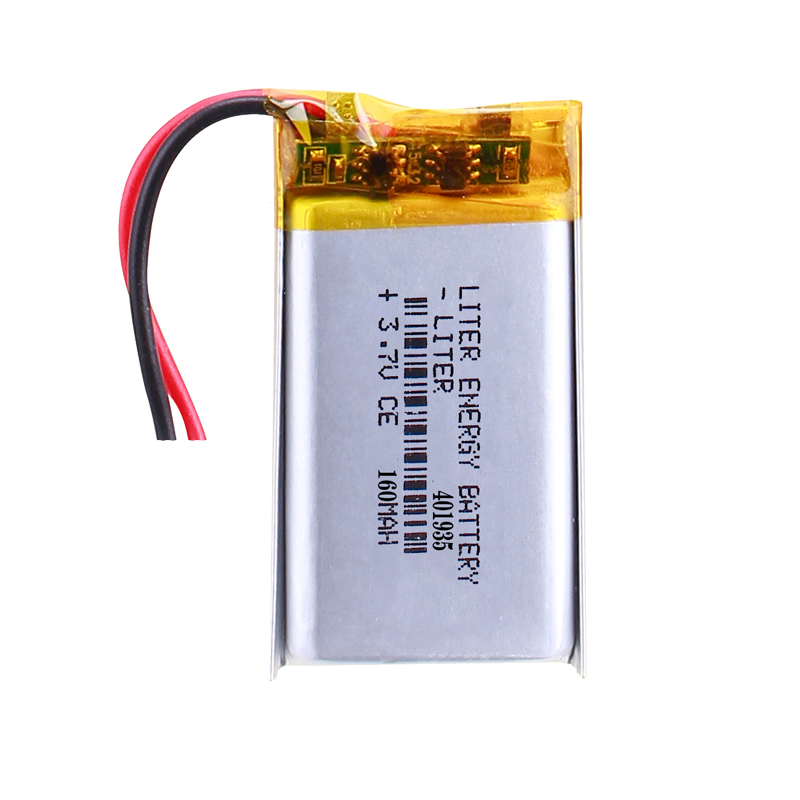

401935 1.5A 160mAh 3.7V Rechargeable LiPo Battery Batteries

Model 4019035 1.5A 160mAh 3.7V Rechargeable LiPo Battery BatteriesType3.7V LiPo Battery Batteries...